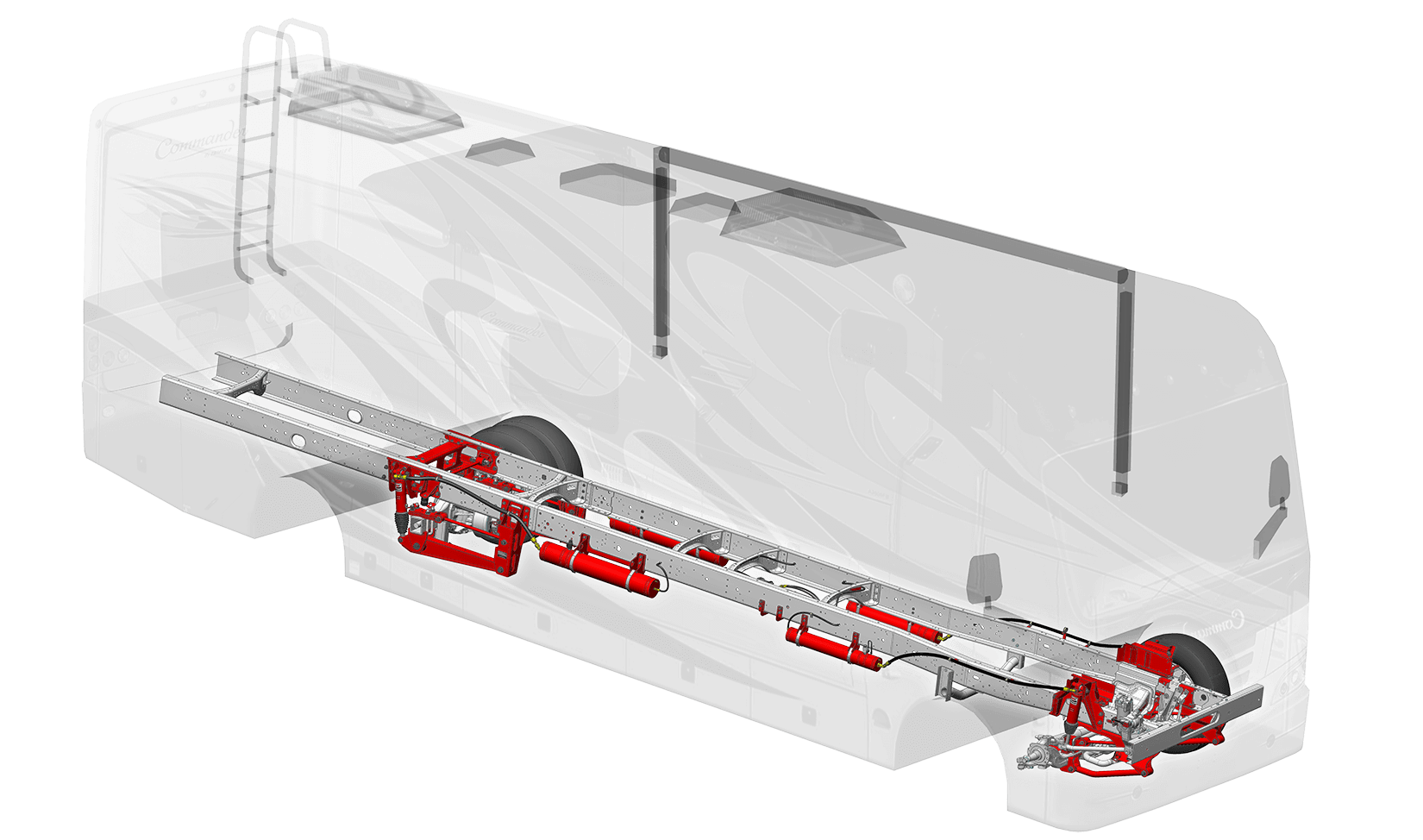

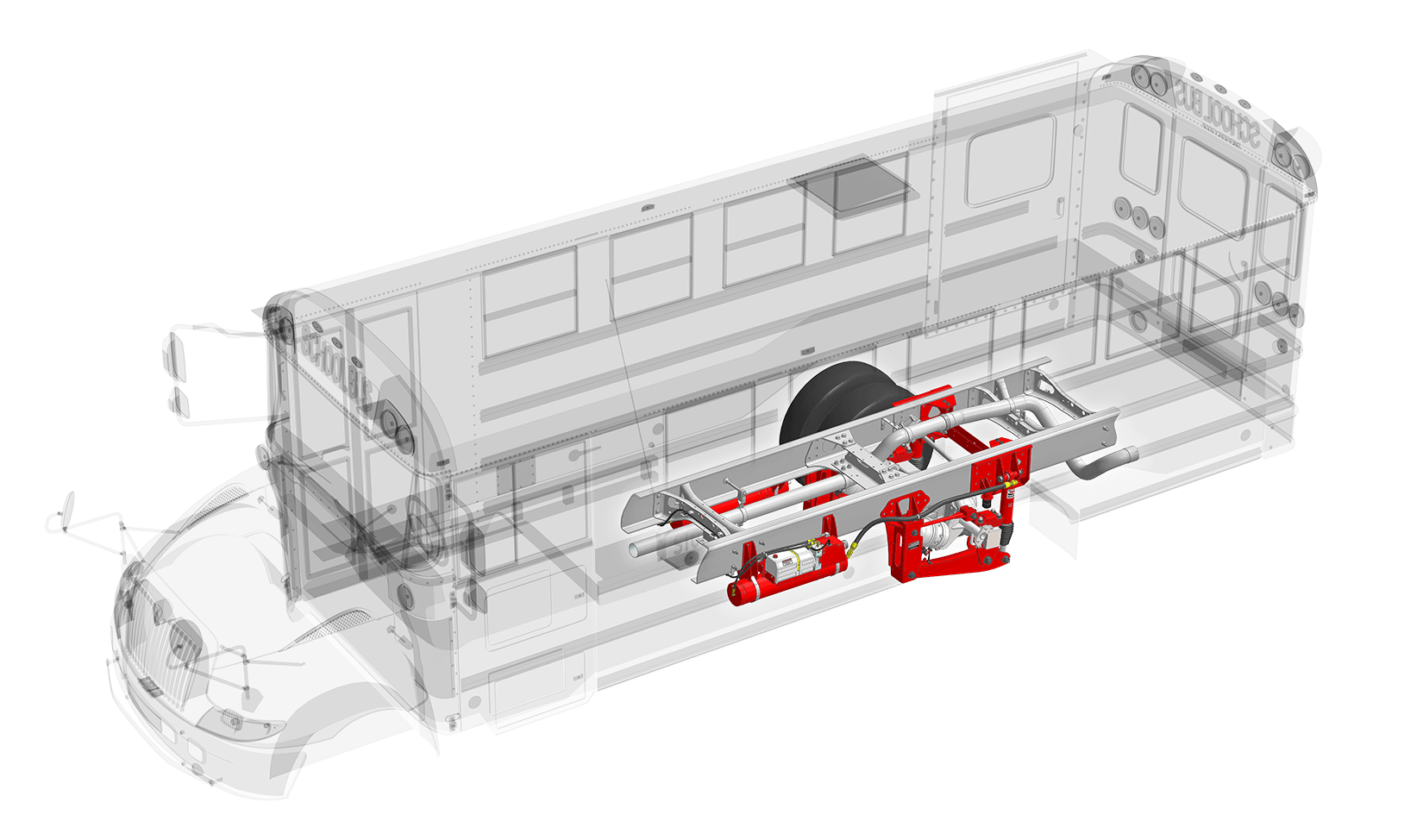

20+ years of engineering and innovation have contributed to a one-of-a-kind suspension system.

Five key components work together to deliver the smoothest ride possible:

20+ years of engineering and innovation have contributed to a one-of-a-kind suspension system.

Five key components work together to deliver the smoothest ride possible: