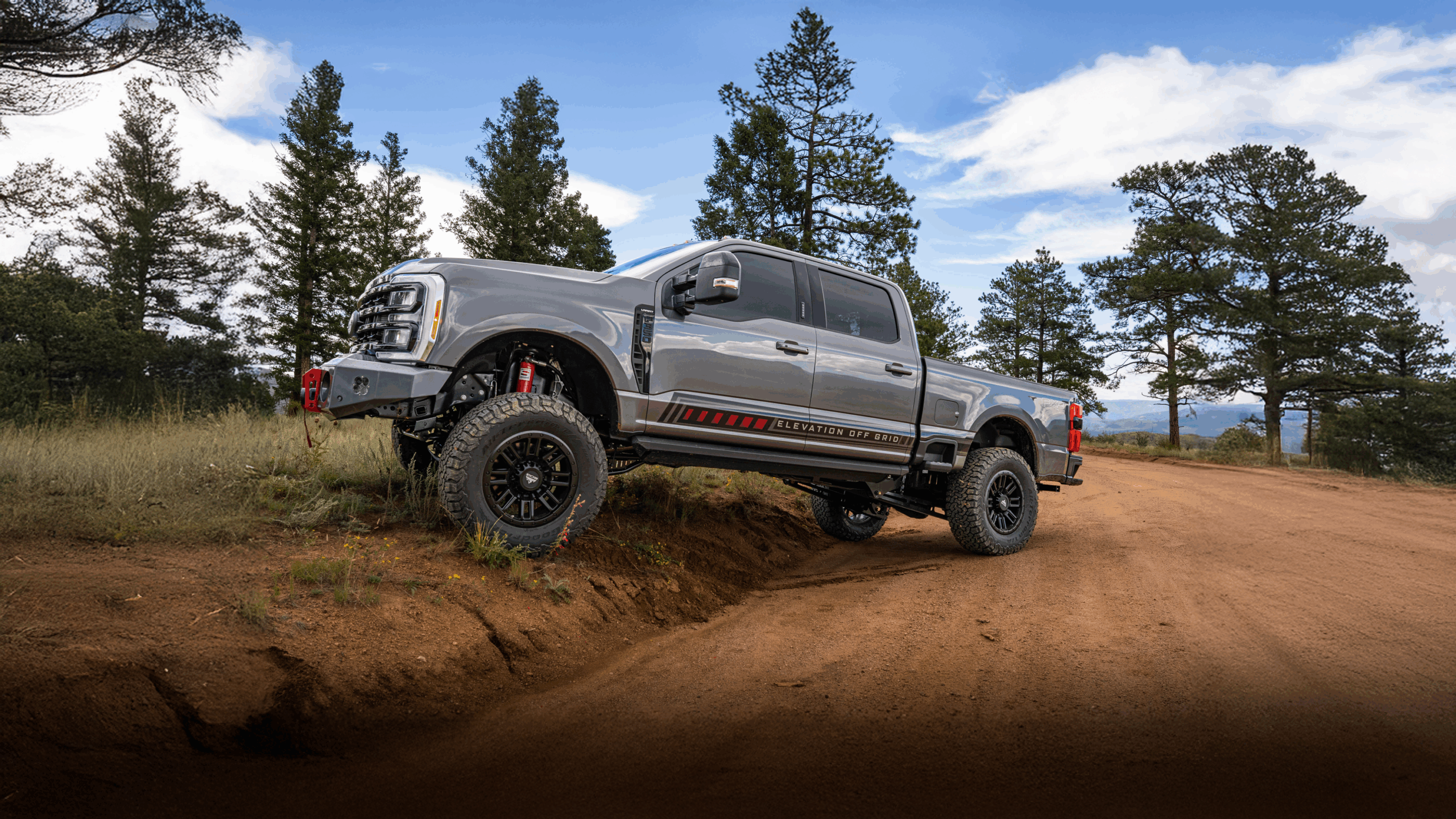

Yes—your heavy-duty pickup can ride as smoothly empty as it does loaded. RideSync™ by LiquidSpring® delivers consistent comfort and control, whether you’re hauling 3,000 pounds or running to the grocery store with an empty bed. This enhanced smart suspension system maintains what engineers call “constant ride frequency”—meaning your F-250, F-350, or Ram 3500 feels the same whether it’s working hard or cruising light.

Here’s how RideSync™ solves the biggest problem with work truck suspension ride quality that forces many truck owners to keep a separate daily driver.

Why Work Trucks Ride Rough When Empty

Medium-duty trucks like the F-250, F-350, F-450, and Ram 3500 are engineered for work. Their leaf spring suspensions are designed to carry heavy loads, tow substantial trailers, and handle commercial upfitting. This makes them incredibly capable under load—but creates a harsh, bouncy ride when empty.

The problem is simple physics. Leaf springs are essentially large metal springs that need weight pushing down on them to compress and absorb road impacts properly. Without that weight, there’s nothing to compress the springs, so they push back hard against every bump and road irregularity.

This creates the classic work truck dilemma: excellent capability when loaded, poor ride quality when empty. Many truck owners solve this by owning two vehicles—a capable work truck and a comfortable daily driver.

RideSync™ eliminates this compromise by maintaining consistent ride characteristics regardless of load.

How RideSync™ Creates Constant Ride Frequency

RideSync™ builds on LiquidSpring’s proven compressible liquid technology with an enhanced system designed specifically for pickup truck applications. Here’s how it delivers a smooth ride whether loaded or empty:

The Dual-Stage System

Stage 1: Light Load Performance When your truck is empty or lightly loaded, additional accumulators provide the compression needed for a smooth ride. This solves the fundamental problem with empty work trucks—a lack of weight to properly compress traditional springs.

Stage 2: Heavy Load Performance As load increases, the system seamlessly transitions to rely more heavily on the compressible silicone liquid for primary suspension duties. This liquid handles the heavy compression forces needed for loaded operation while maintaining smooth, controlled response.

Real-Time Valve Control

The system’s computer monitors vehicle conditions 1,000 times per second and controls valves that connect or isolate the nitrogen accumulators from the suspension circuit. When the computer detects the need for firmer suspension (heavy loads, cornering, braking), it closes these valves to reduce the fluid volume being compressed, creating a stiffer spring rate.

Financial Impact: This dual-stage system means truck owners can consolidate to a single vehicle that handles both work and daily driving duties comfortably.

The Science Behind Smooth Pickup Truck Rides

LiquidSpring® engineers tested RideSync™ Technology against stock RAM 3500 suspension using identical trucks and routes. The results demonstrate how the system achieves constant ride frequency:

Frequency Response Testing

Based on controlled testing with identical 2024 Ram 3500 trucks using nine accelerometers and the same test course:

Stock Ram 3500 Results:

- Empty truck: High frequency spikes (harsh ride)

- Loaded truck: Lower, more controlled frequencies

- 21% difference between empty and loaded ride characteristics

LiquidSpring® Ram 3500 Results:

- Empty truck: Controlled, consistent frequencies

- Loaded truck: Similar controlled frequencies

- Only a 10% difference between empty and loaded ride characteristics

Vibration Reduction Data

The testing measured vibration transmission using industry-standard Root Mean Square (RMS) acceleration and Vibration Dose Value (VDV) metrics:

Empty Truck Performance:

- Stock suspension: High RMS acceleration and VDV readings

- RideSync™: 50% reduction in RMS acceleration, 23% reduction in VDV

Loaded Truck Performance:

- Stock suspension: Better performance, but still significant vibration

- LiquidSpring w/RideSync™: 42% reduction in RMS acceleration, 42% reduction in VDV

LiquidSpring’s RideSync™ Technology delivers measurably smoother rides, whether your pickup truck is empty or loaded.

On the Road Performance

Beyond the controlled testing, LiquidSpring demonstrates its pickup truck smooth ride capabilities in practical applications:

Ride Quality Improvements

- Constant comfort: Drivers report the same smooth ride whether hauling equipment or running daily errands

- Reduced fatigue: Less bouncing and jarring means less driver fatigue on long trips

- Improved control: Better handling and stability in crosswinds and when passing large vehicles

Operational Benefits

- Single vehicle solution: Many customers eliminate the need for a separate daily driver

- Better passenger comfort: Family members willing to ride in the work truck for longer trips

- Professional image: Smoother ride creates a better impression when transporting clients or customers

Durability and Maintenance

RideSync™ is designed for minimal maintenance requirements. The enhanced accumulators are sealed systems, and the overall system maintains LiquidSpring’s reputation for reliability, with basic periodic inspections recommended.

Which Trucks Get RideSync™

RideSync™ represents the latest evolution in LiquidSpring® pickup truck suspension technology. LiquidSpring’s RideSync Technology is available for Ford F250, F350, F450, and RAM 3500 pickups.

Professional Installation Required

- Typical installation time: 4-5 days as part of the full suspension system.

- Available through certified LiquidSpring® installers nationwide

Financial Impact: RideSync™ installation typically pays for itself through the elimination of a second vehicle for daily driving, plus reduced maintenance costs from smoother operation.

Installation and Compatibility

RideSync™ installation requires professional expertise to ensure proper setup and performance. Contact a certified LiquidSpring® installer for specific details about:

- Installation requirements for your truck model

- Integration with vehicle systems

- Timeline and process expectations

Professional installation ensures optimal performance and maintains warranty coverage for your investment.

The Bottom Line: Your Work Truck Can Be Your Daily Driver

RideSync™ solves the fundamental problem with work truck suspension by delivering consistent ride quality regardless of load. The enhanced system provides the compression needed for smooth rides when empty, while the proven LiquidSpring® technology handles heavy-duty performance when loaded.

The result is simple: one truck that handles both work demands and daily driving comfort without compromise. No more choosing between capability and comfort, no more needing two vehicles, no more white-knuckle grocery runs in your empty work truck.

For truck owners who want the smooth ride they deserve without sacrificing the capability they need, RideSync™ delivers constant ride frequency that works as hard as you do.

Ready to experience the difference? Contact your local LiquidSpring® installer to learn more about RideSync™ installation for your pickup truck, or drop us a note and we’ll help connect you.