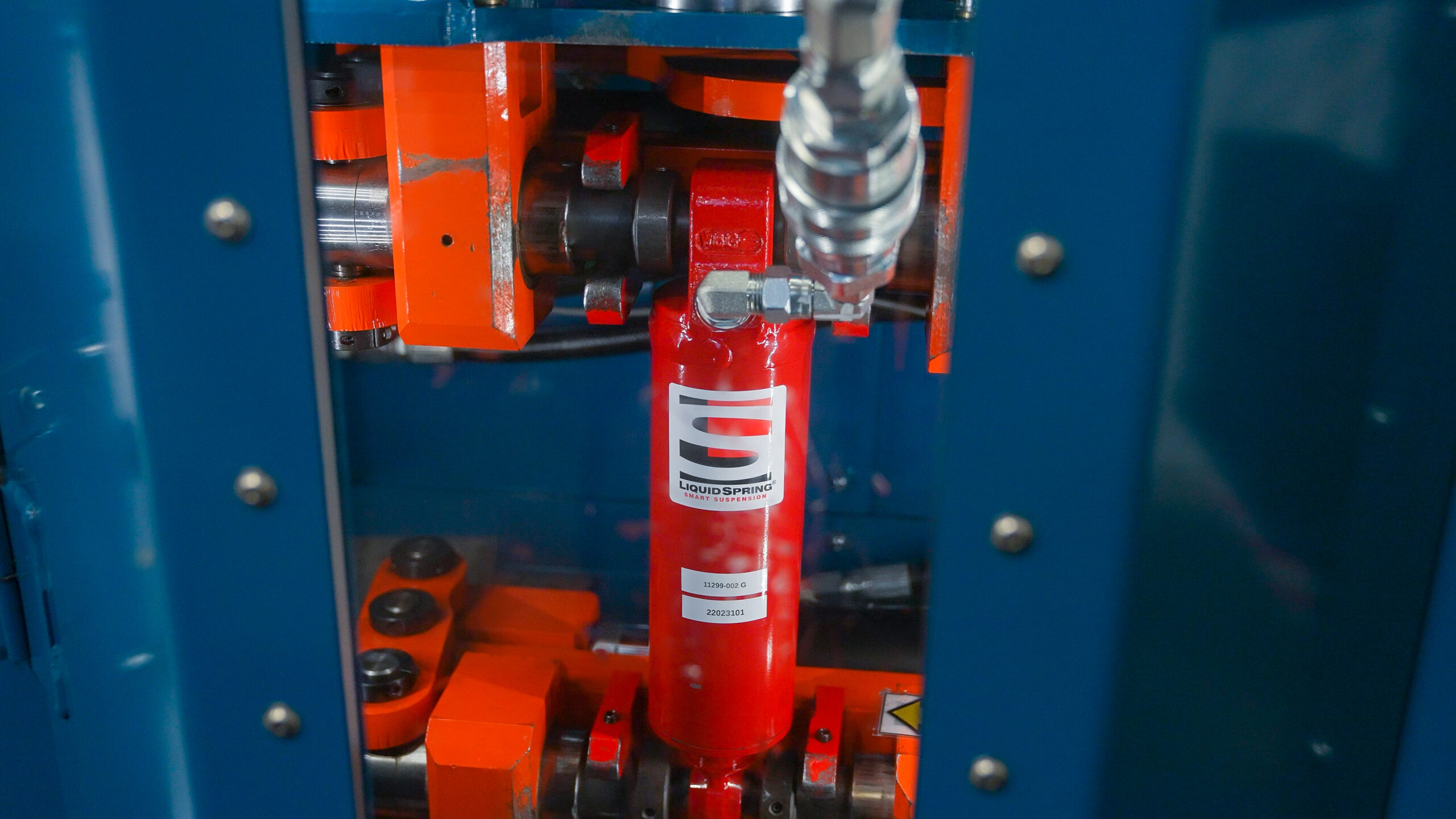

In an era where manufacturing often crosses borders, LiquidSpring shines as a beacon of American pride, showcasing the unmatched quality and innovation that come from homegrown craftsmanship. With a steadfast commitment to American-made products and services, our story is one of celebrating local talent, fostering job growth, and upholding the legacy of American engineering.

American Partnerships: Building on Local Expertise

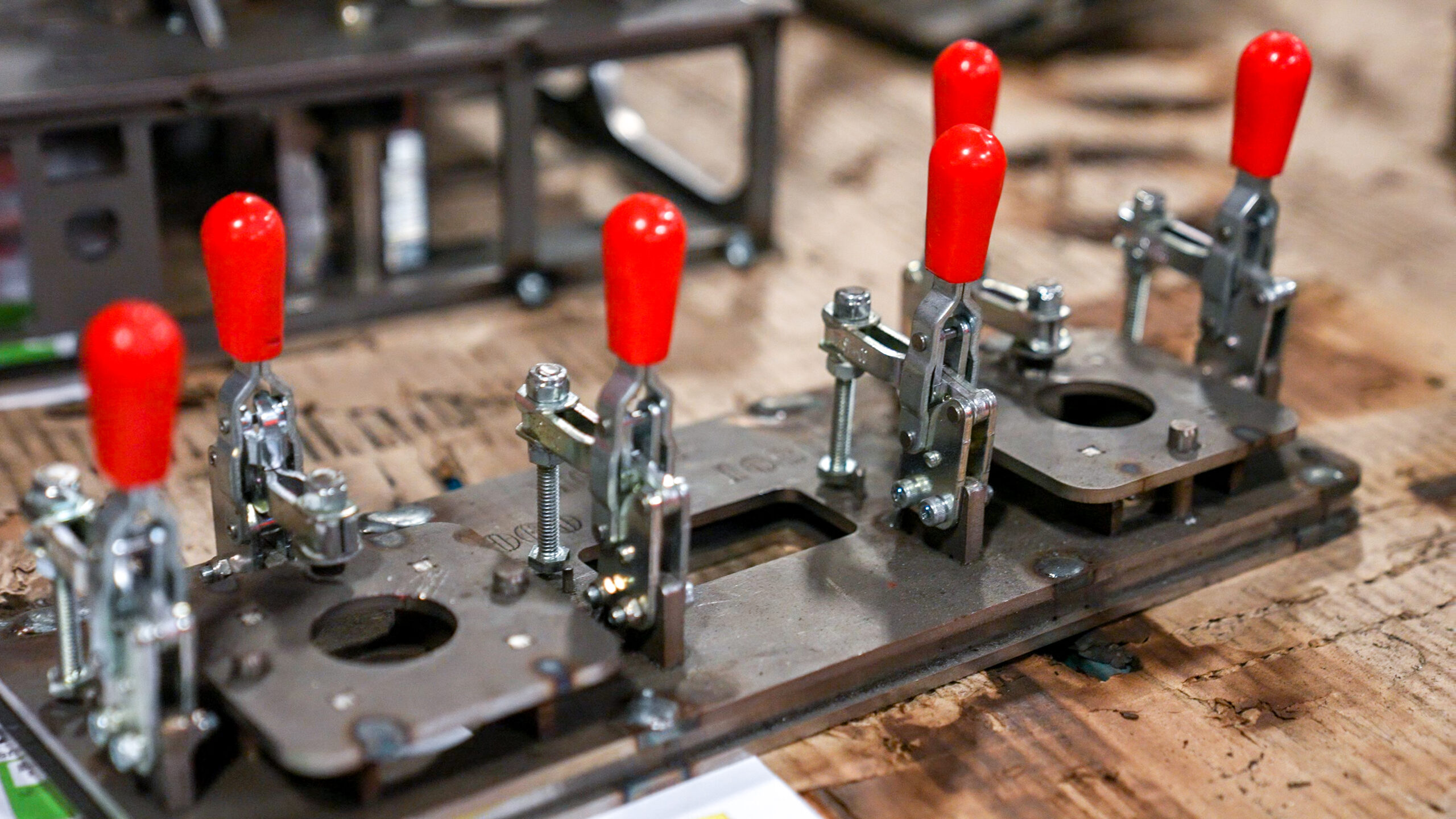

Our American-built ambition is supported through our collaboration with American companies. We tap into a network of domestic partners for various stages of our production process. The amount of work our engineering and purchasing departments have put into sourcing quality, local products and services is extensive, and has resulted in the following:

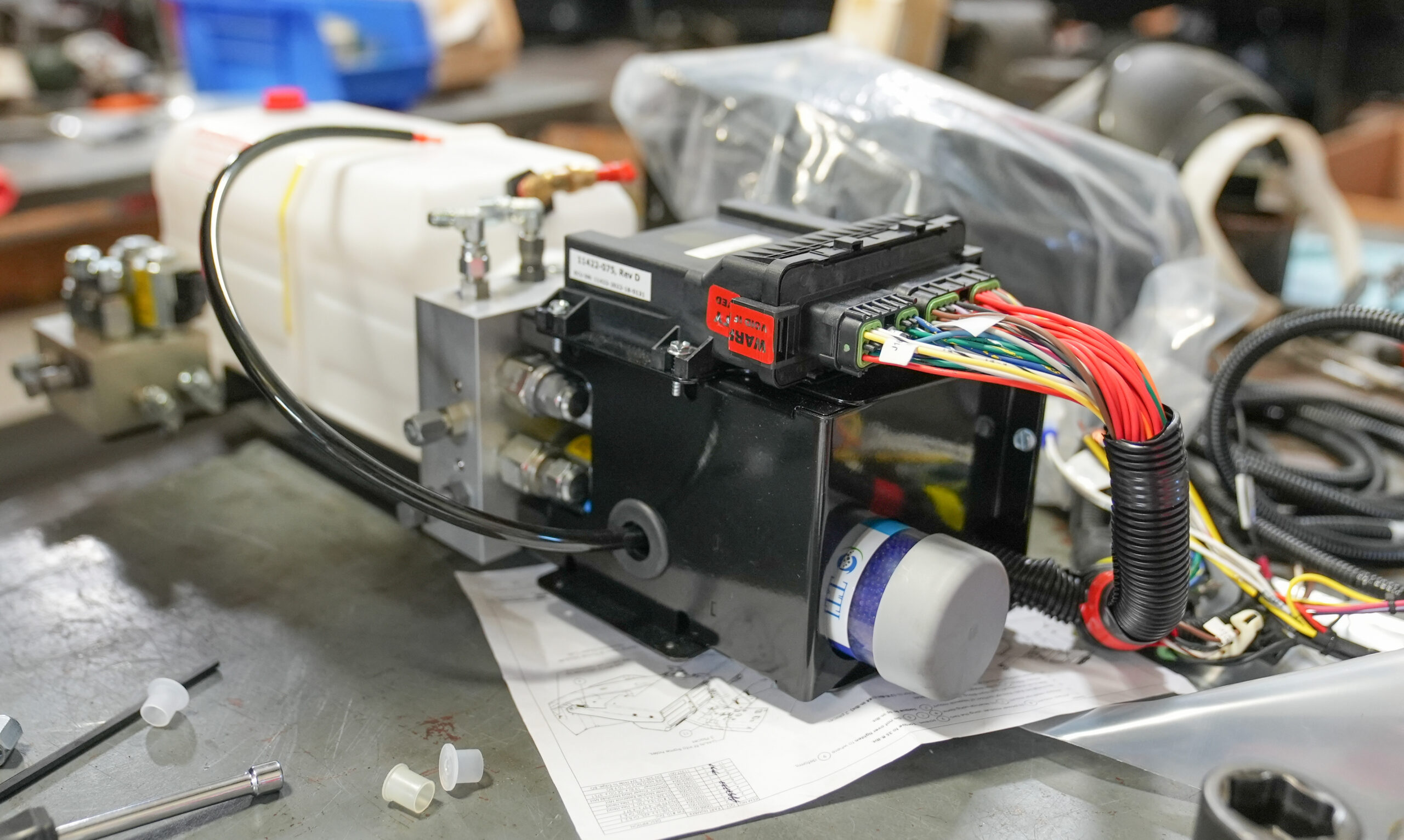

- Wiring harnesses that are made in Ohio and Michigan;

- Bearing spacers, control arms, RV volume tubes, pump couplers, pump coupler guides, sintered bronze filters, and stop collars that are made in Chicago and Indianapolis;

- Rubber bushings that are made in Ohio; and

- Strut end castings and brushing housings that are made in Michigan.

From tube cutting and tube tampering to machining and plating, the companies we contract to support our manufacturing work in tandem with our engineering and development teams to craft high-quality products. Our insistence on using local materials and services when possible not only reflects our commitment to homegrown excellence but also nurtures the growth of local industries.

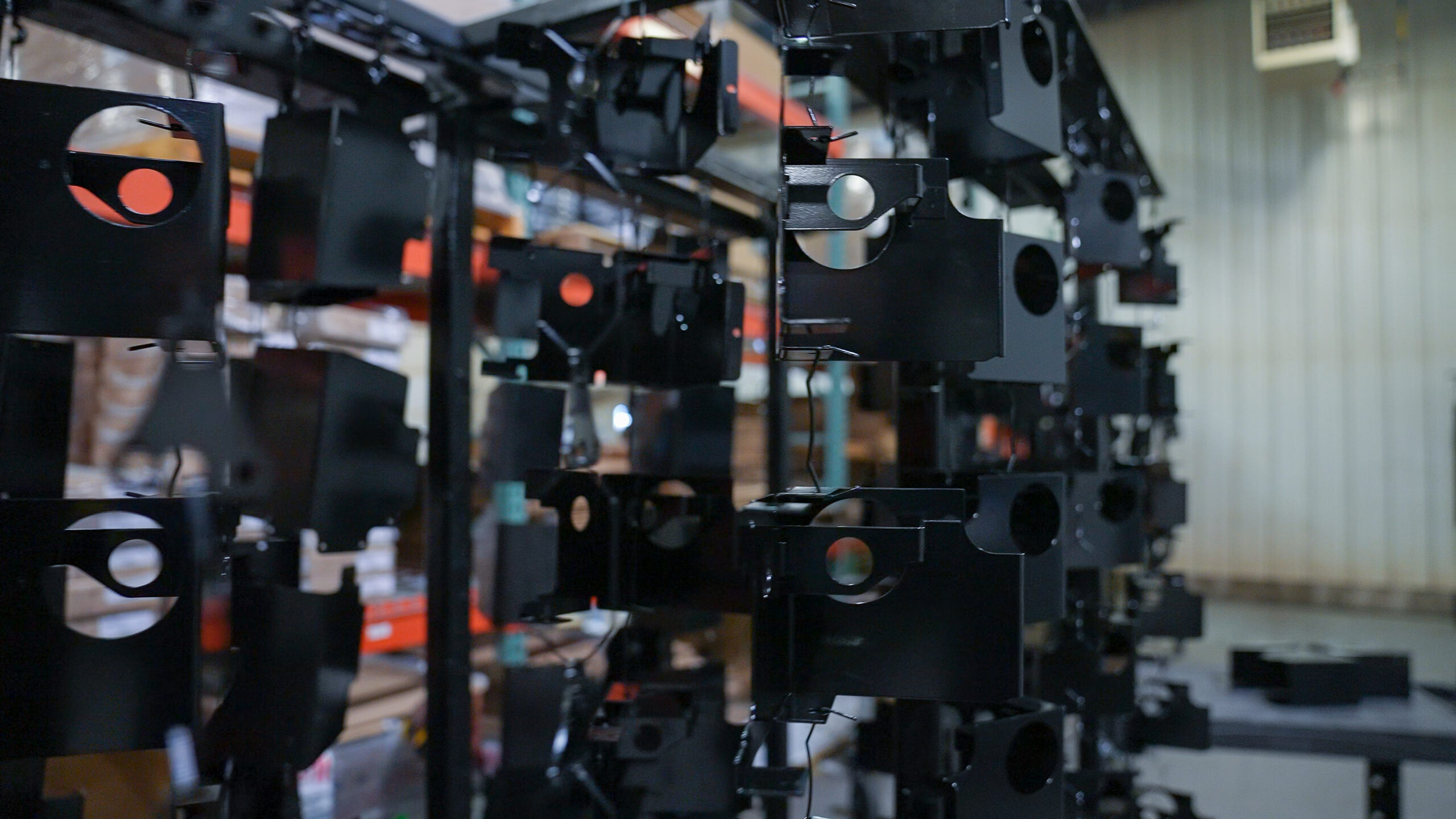

Engineering Excellence: Designing with American Innovation

A key manifestation of our dedication to American-made excellence is evident in our relentless pursuit of cutting-edge innovation. Take, for instance, our recent initiative to redesign our Electronic Control Unit (ECU) using American-made circuit boards. In an industry where global sourcing is often the norm, this move stands as a testament to our commitment to nurturing local technology and manufacturing capabilities. With nearly 90% of circuit boards being produced overseas, LiquidSpring’s decision to bring this critical component’s production back home showcases our financial investment in supporting US tech, manufacturing, and job opportunities.

A Steel Resolve: Fortifying with American-Made Steel

At the core of our commitment to American craftsmanship is the strategic choice to rely on American-made steel. A remarkable 60% to 70% of the steel used in our products is sourced from within the United States. This decision not only supports local steel industries but also ensures the quality and consistency of LiquidSpring products. With the backbone of our creations forged from the strength of US steel, LiquidSpring bolsters both our products and the national economy.

An Intriguing Steel Tidbit: The Allure of Grade 100 Swedish Steel

While we are dedicated to utilizing American resources and products, our demand for incomparable strength resulted in the use of 100 Grade Swedish steel in certain parts of our suspension systems. Swedish iron ore deposits contain small percentages of other metal ores. Which makes steel produced from it a natural alloy. It is Europe’s most high-quality iron ore in its natural state before processing.

A Glimpse into the Numbers: Metrics of Dedication

Behind the scenes, our dedication to excellence is translated into impressive statistics. Producing around 4,000 units per year, LiquidSpring utilizes approximately 100 tons of steel each month, split between sheet and rod/tube varieties. Additionally, every new product brought to market demands an impressive investment of approximately 800 to 1,000 hours of Product Engineering (PE) development time and an additional 200 hours of Mechanical Engineering (ME) development time. These figures underscore our unwavering commitment to delivering quality and innovation to our customers.

____

As a manufacturer, we are proud to place an emphasis on quality and craftsmanship, ensuring the value of our American-made products. From materials to job creation and product innovation, we remain committed to upholding our values and strengthening our products.